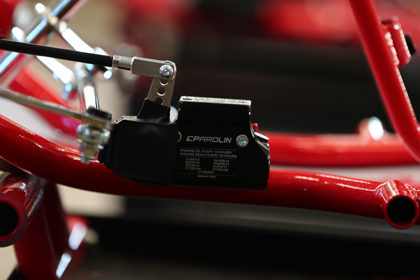

Parolin Racing Kart developed an innovative brake system for the MINI category. This technical solution equips the Opportunity chassis and is characterised by a monobloc rear caliper machined from a solid block with radial attachment.

INTRODUCTION

Thanks to the performances and successes of the Opportunity chassis in the past few years, Parolin Racing Kart has emerged as the benchmark for the MINI class. Parolin’s technicians took advantage of the 2020 homologation, which represents the first of the newly CIK-FIA “certified” versions for the 60 MINI category, to focus on creating a totally new brake system. The AP06 MINI marks an improvement compared to the previous MINI AP-Race model (CSAI homologation), as it features increased rigidity and decreased torsion during braking, while maintaining high levels of reliability.

CHARACTERISTICS

The AP06 MINI’s brake caliper derives directly from the front version of the KZ system. The primary characteristic of this technical innovation is the brake modulation, which represents a pivotal factor when the go-kart requires immediate braking while maintaining high speed throughout corners.

CNC machined from a solid block of material with extreme accuracy, the caliper is equipped with two 27 mm magnetic pistons in order to control the pads’ braking strength on the disc. Parolin technicians’ hard work also resulted in better cooling and in a decrease in the weight of the AP06 MINI caliper thanks to a significantly pronounced tapering. An additional improvement compared to the previous version regards the lower maintenance, achieved as a consequence of the absence of the half-shells’ fastening screws and of the sealing O-rings. Lastly, the total redesign of the oil channels inside the caliper has facilitated brake bleeding, which is now carried out only once, as it is a monobloc caliper.

Furthermore, the floating and self-ventilated brake disc has a 150 mm diameter and features holes on its surface to achieve greater heat dissipation capacity during braking.

FUNCTIONALITY

Parolin Racing Kart completely modified the master cylinder and introduced the model that is used in the higher classes. The outcome includes better reliability, as the different anodising adopted enables the reduction of possible leakages and therefore a lower maintenance of the component. A piston with a 22 mm diameter functions inside the master cylinder, which is machined from a solid aluminium block. Moreover, there are four possible anchoring positions for the lever on which the rod leading to the brake is fastened. This solution offers drivers a wider range of options in order to adapt to their braking preferences. As the rod is fastened lower, the force that needs to be exerted on the brake pedal increases because its stroke becomes shorter. Contrarily, as the lever is higher, the force that is necessary for braking decreases because the stroke becomes longer.

BENEFITS

In addition to the aforementioned advantages, the AP06 MINI benefits from great adaptability. Being aware that adapting braking to driving style is crucial for improving performance, the company’s technicians equipped the new MINI brake with three different types of brake pads: hard (black), medium (green) and soft (red). The degree of hardness of the friction material varies among the different pads, which are all smaller. In fact, Parolin’s experts believe that only the force exerted by the piston on the pad directly impacts on the disc. Consequently, the use of larger pads would represent a risk, as they could cause a lower thrust to the external areas, which is essentially not very useful.

MORE DETAILS

To know more about the AP06 MINI brake by Parolin Racing Kart and discover all its potential, read TKART’s article “AP06 Mini: the 2020 mini-kart brake system by Parolin Racing Kart“.